Headlight protection with polyurethane and tinting film

Headlight Repair & Protection Film Installation in Kyiv • By Appointment Only

Mon–Fri: 09:00–20:00 | Sat–Sun: Closed

Car headlights are exposed to ultraviolet rays, stones, chemicals and sand every day. Without protection, the surface of the optics becomes cloudy, chips and scratches appear, and replacing or polishing the headlights can be much more expensive. That is why covering headlights with protective film (often called headlight armouring) is a popular solution for motorists in Kyiv who want to preserve their optics without unnecessary expenses.

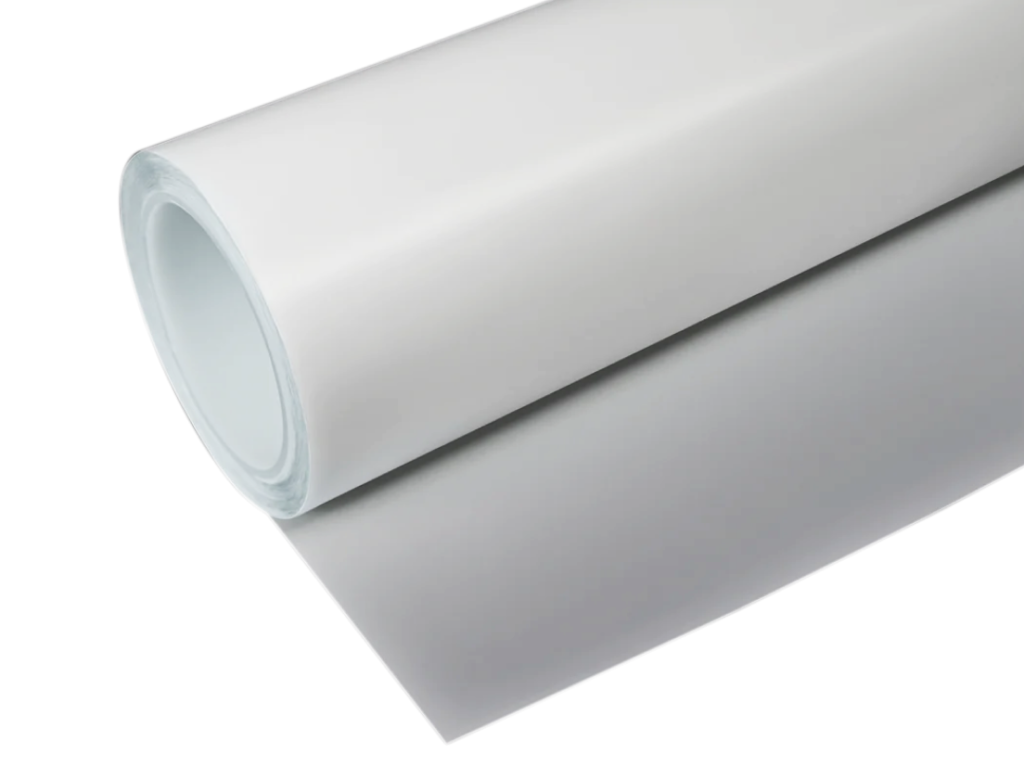

Covering headlights with protective polyurethane film (protective film for headlights / headlight covering / headlight armouring in Kyiv) is a modern solution for those who want long-lasting protection for their optics from damage and loss of transparency.

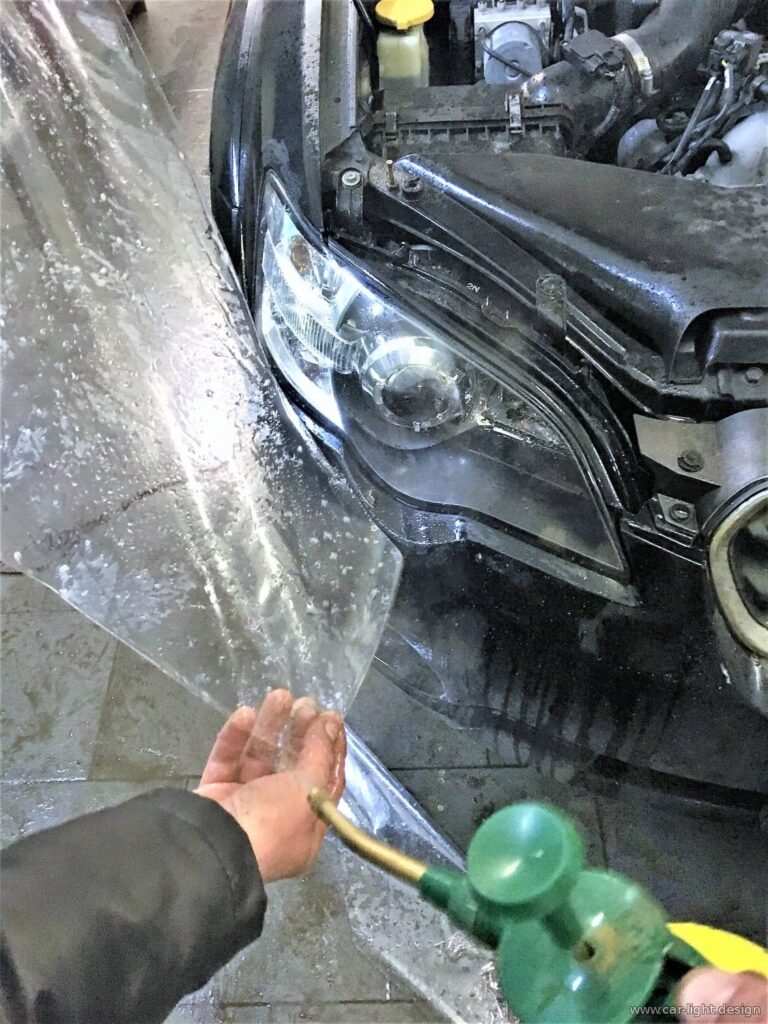

At Car Light Design, we perform professional headlight protection in Kyiv using high-quality polyurethane and tinting film that preserves transparency and enhances the style of the car.

Protective film for headlights is one of the most effective ways to extend the service life of car optics. Headlight protection is often combined with headlight polishing to consolidate the result and prevent re-wear of the coating.

The protective film service for headlights in Kyiv allows you to achieve a stylish look and ensure long-term protection of the optics without the need for replacement.

Protective film for headlights in Kyiv acts as armour for headlights — that is why the process is called headlight armouring.

We offer two options for headlight wrapping in Kyiv:

For those who are considering tinting their headlights with film in Kyiv, we will select the shade and install it in accordance with safety standards.

Covering headlights with film is an investment in the longevity of your optics.

Unlike lacquer coating or painting, the film can be easily removed without damaging the factory glass. This makes headlight protection the ideal solution for both protection and tuning. If you want to comprehensively modernise your car’s lighting, take a look at our lens and LED module installation service.

Polyurethane film lasts 3–5 years, maintaining its transparency and not yellowing over time.

Yes, the film can be removed without leaving any adhesive residue and does not damage the optics.

The transparent film does not reduce the light output. The tinting film is applied in accordance with applicable standards.

Yes, if the headlights are already cloudy or have minor damage, we recommend polishing for a perfect result.

Level of protection: polyurethane film offers the best protection against damage. Aesthetics: vinyl film is available in a variety of colours and patterns. Durability: polyurethane film is more durable than vinyl.

Polyurethane film is considered the most reliable protection for the car body against negative influences: gravel, sand, rubble, impacts, scratches and abrasions. Anti-gravel film is completely transparent, it does not cloud or yellow over time.

Yes, it does. According to the Traffic Rules of Ukraine, in particular paragraph 31.4.3, it is prohibited to operate a vehicle with external lighting devices that have been modified in such a way that they reduce their light transmission capacity or impair visibility. If the tinting film or any headlight coating changes the light characteristics or darkens the headlights, this may result in a fine, vehicle impoundment, or loss of driving privileges. Therefore, when covering or tinting headlights, it is important to use a transparent protective film that does not violate regulations and to consult professionals, such as those at Car Light Design, to avoid legal risks. Ask our specialists about permissible darkening to be sure that your headlights are legal.

The time required to apply protective film to headlights may depend on several factors: the condition of the headlights, whether preliminary polishing is required, the type of film, and the workload of the service centre. The procedure for applying film to headlights in Kyiv usually takes 1.5-3 hours, but the final time is specified when booking. If the headlights need to be polished before wrapping or the work is more complex (sports cars, non-standard optics), the time may be longer. In any case, the Car Light Design team in Kyiv will provide an accurate time estimate after inspecting your car.

Want to cover your headlights with film, protect them and improve the appearance of your car? Sign up for headlight film application at Car Light Design, and we will select the best option for your car.